FAQs

- How Do I Measure a Rod Guide?

- Ceramic Centre Types what is the difference?

- DLC, TIC and TIN what is it and how does it last?

- Do the rod blanks carry a life time warranty as some Rods do?

- Do we export?

- Do you have any information about sizing guides?

- Is there any more information about the Rod Smith Power Wrapper?

- What is the difference between English pattern & American Pattern snake Guides?

- Which are better Snake Guides or Lined Guides?

- Why are our guides so much more durable than our competitors?

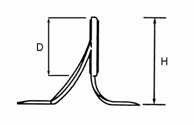

How Do I Measure a Rod Guide?

The Height is measured from the base to the top “H”

The Diameter is the size of the out side of the ceramic liner (not the frame) “D”

On Tip Guides the Tube Bore “TB” is the internal diameter of the tube this should be just a fraction bigger that the outside diameter of the rod blank to allow for some glue.

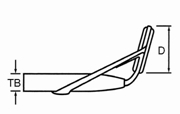

The Anatomy of a Rod Guide

Ceramic Centre Types what is the difference?

There are lots of types of centres but generally they can be split into 4 main groups based on the material they are produced from.

These are Porcelain, Alumina Oxide, Silicon Carbide and Titanium Nitride/cermet.

The biggest group by far is Alumina Oxide with different manufactures altering the colour and even adding coatings on top of the ceramic to alter the appearance.

| Name | Colour | Material | Hardness in Vickers |

|---|---|---|---|

| Fuji gold cermet | Gold | Titanium Nitride Cermet | 1100 |

| Fuji SiC | Silver/Black | Silicon Carbide | 2200 To 2400 |

| Fuji Alconite | Black | Reinforced Alumina Oxide | 1300 To 1500 |

| Fuji Hardloy | Grey | Alumina Oxide | 1200 To 1400 |

| Fuji Hard | Dark Grey | Alumina Oxide | 1200 To 1400 |

| Fuji "O" | Dark Brown | Alumina Oxide | 1200 To 1400 |

| Seymo Superglide | Brown | Alumina Oxide | 1200 To 1400 |

| Seymo Hardlon | Dark Brown | Alumina Oxide | 1200 To 1400 |

| Seymo Titania | Grey | Alumina Oxide | 1200 To 1400 |

| Porcelain | White | Porcelain | 550 To 650 |

All of these centre types have there own benefits, and all the centres will handle mono fishing lines. If you use braded lines we recommend that you use Alconite, Sic or Cermet. But be warned there are lots of copy products like this, where a softer alumina centre has simply been painted or chemically plated to make it look like Sic or Cermet. It pays to buy a branded product.

DLC, TIC and TIN what is it and how does it last?

All of these are different types of coatings that H&H can put onto there range of snake guides and tip tops. DLC = Diamond Like Coating, This is a titanium nitride coating, during the coating process Argon gas is added to give the black/blue finish.

TIN=Titanium Nitride Coating is exactly the same as above but with out the argon gas this leaves a gold finish. TIC= is the same but has an ebony gun smoked finish. All of these treatments were originally developed and used to coat drills, machine cutters and bearing parts to give a lower coefficient of friction and improved ware resistance.

IN all of the finishes H&H take there Hard Chrome snake or tip top and then have this coating applied to it. Why? Because it gives a very hard substrate for the coating to adhere to. It is best related to a pond that freezes over in winter, if you take a hammer and hit the ice you will smash through. However if you take a small amount of water and pour it onto a road , that freezes , you hit it with a hammer , the hammer will bounce off because of the hard substrate, That's why H&H put these types of finishes over hard chrome , Unlike Pac Bay who coat directly onto the bear wire. This also means that if the coating does were off you are safe in the knowledge that you have hard chrome underneath.

Do the rod blanks carry a life time warranty as some Rods do?

All the Rod blanks we sell are covered against all manufactures faults and Defects. Obviously the workmanship done on a rod blank is not warranted in any way.

Do we export?

Yes we do, to all people in EEC we have to charge VAT unless they can provide a VAT number. For the Rest of the World we can deduct the VAT.

Do you have any information about sizing guides?

Yes. You can download our sizing guides below.

A mm to 1/64 conversion chart can be found here.

Downloads

Is there any more information about the Rod Smith Power Wrapper?

Yes. You can download our Power Wrapper PDF below.

Downloads

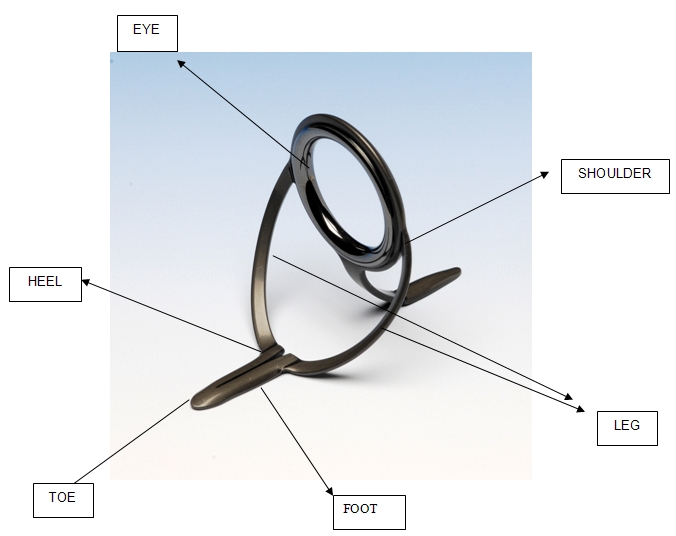

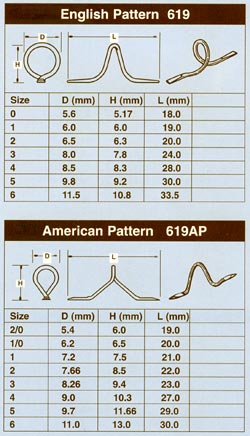

What is the difference between English pattern & American Pattern snake Guides?

In terms of raw materials and hard chroming of the guides there is no difference, the difference is all down to the shape or form of the guide. An American pattern is coiled left to right, it has straight legs and stands off higher. The English pattern is coiled right to left and is round in profile with sweeping legs, it is also a lot lower set.

In years of practice we have found that an English pattern is

better suited to a softer, slower action blank than an American

pattern which is by far better on a fast action blank. We proved

this theory by putting American pattern snakes onto a soft slow

action blank in a relatively short time of use the inside legs were

showing sign of ware and in fact the Epoxy on the whippings were

actually grooved, We changed the guides back to English pattern and

tested again, over the same test period no ware was detected.

Dimensions of English and American pattern Snake Guides

Which are better Snake Guides or Lined Guides?

This is a commonly asked question, and at the end of the day it is down to the individual angler, how they fish and the type of fishing they do. Lined guides especially Fuji or Seymo will not grove as fast as a snake guides, but the surface area of any lined guide is much greater than a snake guide so this will increase the friction and reduce the length of line cast. It is a trade off, but be sure to use H&H snake guides as they are by far harder, than all others on the market.

Why are our guides so much more durable than our competitors?

All our guides are put through a vigorous abrasion testing machine. The diagram below shows the machine system layout, also displayed are the exact conditions for the testing.

Condtions

| Line | nylon 9 lb line fly #4-DT-F line |

|---|---|

| Load | 700 g |

| Angle of line contact | 90° |

| Solution | 1% muddy water (mud 10g + water 1000ml) |

| Speed of line | 60 m/min |

| Distance | 3000 m |

For the following results two samples were identified:

- X SNG (PAC.BAY) Size 3

- 619AP - HC (SEYMO) Size 3

The above samples wer submitted to the laboratory for hardness determination of the chromium plating and coating thickness.

Coating Thickness

The coating thickness was determined in accordance with BS 5411 Part 5 (SGS Test Procedure E5TP 002.3). The measurements were made using the AMS 40-10 Image Analyser in accordance with SGS Test Procedure E5TP 002.13.

| Sample | Local Thickness (µm) | |

|---|---|---|

| Range | Average | |

| X SNG | 9.8 - 12.7 | 12.2 |

| 619AP | 18.4 - 25.8 | 21.3 |

The coating thickness of each is illustrated in Figures 1 an 2 (see below) respectively.

Hardness Testing

The hardness testing was determined on the prepared cross-section using the Leitz microhardness testing machine with a load of 100g.

| Sample | HV (01.) kg(µm) | |

|---|---|---|

| Range | Average | |

| X SNG | 874 - 891 | 882 |

| 619AP | 1064-1097 | 1081 |

| Coating of sample X SNG - Unetched (x400) | Coating of sample 619AP - Unetched (x400) |

|---|---|

|

|

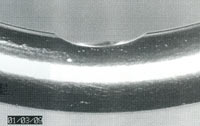

The photographs below show how the hardness of the chromium plating and the coating thickness effect the durability of the guide.

| Snake guide / Ti II wire (no treatment) | Snake guide / Ti II wire (tempering) |

|---|---|

|

|

| abrasion wear: 323 µ m | abrasion wear: 439 µ m |

| Snake guide / plate ST wire with chromium | Snake guide / plate ST wire with chromium |

|

|

| abrasion wear: 86 µ m | abrasion wear: 101 µ m |

Condition

test line: fly line #4-DT-F